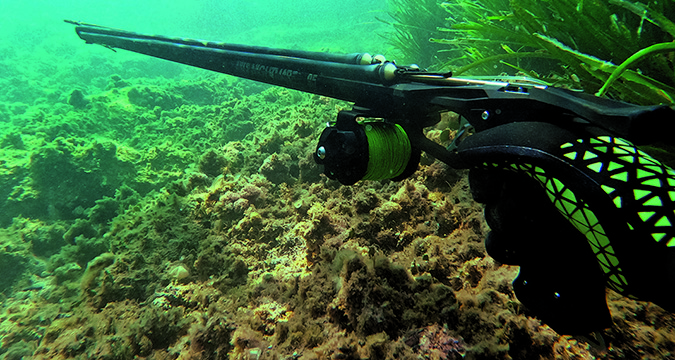

Salvimar: Ares Nightmare 95 Speargun

CETMA COMPOSITES: Taras and Lotus Carbon the 2 custom-made fins!

20 May 2024

C4: Storm Fins

20 May 2024The latest version of this successful series features dual 14.5-millimeter bands and a 7-millimeter Bolt shaft. This is a well-constructed speargun that has proven to be highly maneuverable even in shallow waters with strong swells

Cristian Righetti

The Salvimar 2024 catalog offers several new products, among which the latest version of the Ares speargun, the Nightmare, stands out. This engineering marvel differs from the Ares "classic" in both aesthetics and configuration. Aesthetically, the Nightmare features gray prints (while the "classic" has lime green), and the sight notch and the bottom part of the handle (which houses the 4-millimeter stainless steel attachment ring) are black instead of lime green as in the "classic." Additionally, the kit’s nylon line is transparent in the Nightmare, whereas it is lime green in the "classic".

The main differences lie in the configuration. The Nightmare is equipped with dual 14.5-millimeter Salvimar by Primeline rubber bands (latex) and a 7-millimeter Bolt shaft, a more robust setup compared to the "classic," which has dual 14.5-millimeter bands and a 6.5-millimeter Bolt shaft.

When I first opened the sealed plastic bag containing the Nightmare 95, I was most surprised by its weight (1.285 kilograms without the reel); it is surprisingly light: I like it! On dry inspection, its innovative shapes, especially the ribbed barrel, are highly appreciable. Let's now examine the individual components in detail.

The open head is molded (like the handle) from 30% glass-filled nylon. It is compact and not bulky, with bilateral spurs. It connects to the barrel via a cylindrical male fitting with dual O-rings and is aesthetically finished to appear as a continuation of the barrel’s ribs. The holes for the bands (14 or 16 millimeters) are designed to align the rubber perfectly with the shaft tabs; the spacing is about 35 millimeters, matching the distance between the two loading tabs of the Bolt shaft.

At the front of the head, there is a level-like feature that the shaft’s fin rests on (mounted below), preventing it from opening; thanks to this design feature, there is no need for an O-ring to keep the fin closed. Also at the front, there are two deep grooves for the nylon line, allowing optimal placement of the line without the risk of it slipping off.

The matte black barrel is made of aluminum alloy, with an asymmetric elliptical section, external reinforcing ribs (14 of them), and an integrated shaft guide. The ribs serve to strengthen and stiffen the barrel without adding weight. It is defined as having a "multiple edge geometry," standing 26 millimeters tall, finished with black anodization, and featuring logos imprinted through pad printing. It fits seamlessly into the handle, with a watertight seal ensured by dual O-rings.

The ambidextrous neutral handle has a near-classic grip and showcases clean lines. The black thermoplastic base closure is secured by two stainless steel pins and is removable; the pins also secure the rear stainless steel hook. The surface of the grip is smooth on the sides and slightly roughened on the front and back portions to ensure a stable hold even with gloves.

The fixed sternum pad is slightly curved downward and measures about 60 millimeters, greatly facilitating loading. Its curved shape also offers an immediate sightline to the rear sight notch (glossy black plastic) located at the back of the trigger box. This provides a clear sightline, resulting in a quick and intuitive aiming system called Line Of Sight Collimation. The safety is a button: when it is flush on the right side and protruding on the left, the Nightmare is ready to fire.

A pin secures the small stainless steel box housing the trigger mechanisms. As with all stainless steel details, the components are produced via injection molding at the Salvimar plant. The line release mechanism, which is interchangeable for right or left use, is made of 17/4 PH stainless steel, comes out of the mold with smooth and perfectly rounded edges. Inside the trigger box, the special Rfsc (Rolling, Friction, Self Centering) mechanism is found, a lever system with rolling friction self-centering release, covered by a patent. The trigger is made using a micro-casting process, specifically Metal Injection Molding (MIM), and features a large skeletonized design with smooth surfaces. A groove at the top centers the release tooth’s roller, stabilizing it for precise operation. Sensitivity can be adjusted with an Allen head screw; simply tighten or loosen it to achieve the desired sensitivity.

The rubber bands are the Salvimar by Primeline "Prime black" type, 14.5 millimeters. Primeline uses a continuous immersion process where the rubber is produced through a layering process, offering high physical properties with less than 50 micrograms of proteins per gram. Extracted from the Hevea Brasiliensis tree, it is processed in its original liquid form, achieving a uniformly distributed formula. The result is a product with excellent physical properties, including increased tear resistance.

The Bolt shaft is made of 17/4 PH stainless steel with laser welds. Thanks to a special milling of the notch, it pairs perfectly with the trigger box. The Nightmare 95 comes with a 125-centimeter long Tahitian shaft, featuring a patented Line Of Sight Collimation system. This solution keeps the arrow aligned with the shaft guide, preventing lateral movements. This means that upon release, the energy from the rubber bands is transferred to the center of the push, minimizing oscillations. The result is a very precise, stable shot with greater penetration.

The Nightmare is available in sizes 75, 85, 95, and 105.

At Sea

It’s March, a month not ideal for coastal fishing, but a movement of currents has created lively waves despite the absence of wind. In these conditions, I prefer using light weapons, easy to handle and maneuver quickly, and at least on dry land, the Nightmare seems perfectly suited for the purpose.

Here I am in the water. I load the speargun: the first band to be armed is the one inserted in the outermost hole; it is passed under the circular band of the second hole and stretched to the second-to-last notch. The second operation involves passing the remaining Prime band onto the last notch. I realize that the sternum pad, thanks to its generous size, alleviates any discomfort from the pressure on the sternum.

I start finning. The Nightmare has a slightly negative balance towards the handle. To fix this, I recommend removing the attachment ring and replacing it with a dyneema loop, which should lighten the rear end of the speargun.

The maneuverability is impressive; it feels almost like holding nothing at all. The short 125-centimeter shaft contributes to this sensation, especially during lateral movements. I want to head to a reef where the waves break heavily. It’s an almost extreme situation, but I know I’ll encounter some notable prey.

I perform a stealth approach to get close to a rocky area where I will set up an ambush; usually, this spot sees bream, gilthead bream, and some sea bass. As soon as I position myself, I see 4 or 5 gilthead bream emerging from the bubbles of a wave that gradually disappear; they are not huge, but still decent fish. They give me enough time to aim at the largest one, which ends up on the line. The trigger has incredible sensitivity, possibly never experienced before, while the recoil is noticeable but manageable. I have a habit of keeping my wrist rigid to absorb part of the recoil. Indeed, the Bolt shaft pierces the fish right in the center of its body. Once unloaded, the speargun has appreciable buoyancy.

Satisfied with the shot and the catch, I continue along the reef towards the open sea, heading to a strip of granite where the waves break. Here, the fish stay in the space between the surface and the tops of the granite rocks, but it’s not easy to shoot as the strong waves complicate the action. The script is well-practiced from many years of experience. I keep the Nightmare parallel to my body but slightly advanced during the approach on the bottom. In front of me, I see the white rocks, and above, a sea bass is stationary, as if letting itself be caressed by the foam. I start to extend my arm; the current is strong, making it difficult to keep the speargun aimed, but thanks to the lightness of this speargun, I have no trouble and manage to pierce the fish right in the center, immobilizing it.

As a first test, I must say it exceeded my expectations, and all the positive impressions were thoroughly confirmed in subsequent outings (at least five or six) under different marine conditions. In short, this Nightmare is a real gem!

Ratings

Construction Technique: 9

Salvimar has the undisputed merit of seeking constant innovation in its products. The Nightmare is entirely built in the Ligurian plant using techniques studied, developed, and patented there. Every component is made from top-quality materials.

Finish Level: 9

It’s the details that make this speargun great: the trigger, line release mechanism, handle, ribbed barrel, head, band bindings, and shaft. It’s near perfection.

Balance: 8

When loaded, it tends to be negative towards the handle. This can be mitigated by removing the stainless steel ring under the handle. The overall balance is good and does not tire the arm.

Maneuverability: 8.5

Excellent in all directions. The Nightmare 95 has proven effective even in shallow waters with strong swells.

Performance: 9

Good range. When pressing the trigger, you almost don't notice anything due to its softness and sensitivity. The 14.5-millimeter Primeline bands, paired with the 7-millimeter Bolt shaft, guarantee excellent thrust and penetration to the end of the line.

Value for money: 9

It costs around €210 without the reel. Definitely money well spent for a reliable product made in Italy.